Why China's Thorium-Fueled TMSR-LF1 Reactor is a Really Big Deal

Part II: Why the TS-MSBR can make Nuclear cheaper than coal & gas, while LWRs can't

Introduction

Part I gave the history of how China’s TMSR-LF1 came to be. But who cares? So what that China built a tiny little research reactor out in the middle of the Gobi desert, based on a 65-year old design for an American proof-of-concept reactor that ORNL only bothered to build one of before abandoning the design! Why should anyone care that China has one now, or that it’s more advanced than the one ORNL built back in the early 1960s? As this post will explain, the answer is that (in my ever-so-humble opinion) this design has more potential to make nuclear energy cost less than fossil fuel energy than any other reactor design ever conceived.

This post will argue my case, and I welcome critical feedback from those who disagree in the comments below. If China establishes a firm lead over the rest of the world in commercializing this reactor technology, I predict that will have profound macroeconomic and geopolitical consequences. Part III will argue that case under separate cover.

To frame the context of this analysis, all my research focuses on how to make nuclear energy limitlessly abundant, and cost less than energy from coal & gas. See The Nuclear Henry Ford Moment for more on why I think this should be our primary goal.

I contend that in the 2020s and beyond, we’re entering the Second Nuclear Era that Alvin Weinberg wrote about in his autobiography. Because the global political will to end humanity’s dependence on fossil fuels is so strong, if we could just get the cost of nuclear down to below the cost of energy from coal and gas, and if we could find a way to build nuclear power stations in the same or less time than it takes to build a gas-fired powerplant, then there would instantly be virtually unlimited demand for nuclear energy to fully replace all the energy we get from fossil fuels today.

Why not stick with what already works?

As of March 2025, there were 411 operating commercial nuclear power reactors worldwide producing 371 GW of electricity. 94 of them are in the United States, spread across 58 power plants in 28 states. 100% of the U.S. reactors and over 90% of all 411 reactors worldwide are of a design category known as Light Water Reactors, or LWRs for short. In simple lay terms, that means these reactors use ordinary water as their core coolant. LWR technology was originally developed in the early 1950s for the USS Nautilus nuclear submarine, and has evolved over the years into modern civilian nuclear power stations.

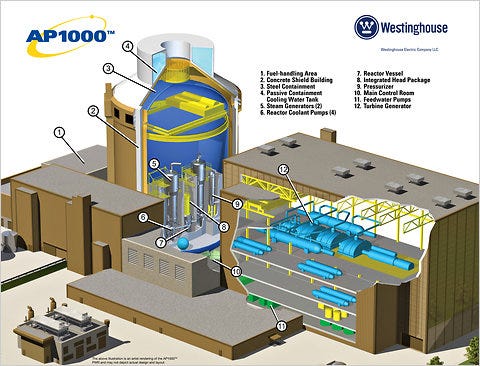

The latest generation of LWRs are known as Generation III+. After decades of operating experience running LWRs, we’ve perfected the design to the point these are arguably the safest and most reliable complex machines ever built. The Westinghouse model AP1000 is generally respected as the current best-in-class American LWR design.

Generation III+ reactors’ automation systems are designed to prevent the kind of human errors that caused all the major accidents, and their safety systems rely wherever possible on passive designs relying on gravity, for example, rather than mechanical systems like diesel backup generators which might fail to work at the worst possible time, as happened at Fukushima Daiichi.

With an introduction like that, why not just keep building more Generation III+ LWRs until we have enough to completely replace the energy we derive from fossil fuels today? First of all, we should build as many new LWRs as we possibly can. This is the proven technology that works and which we know how to build, so we should build as much more of it as we can. But it will never be enough to replace fossil fuels. Why do I say that so adamantly?

Because LWR technology with a “once-thru” uranium fuel cycle simply cannot scale to the degree needed to replace fossil fuels. In order to scale up nuclear energy to replace fossil fuels as our primary energy source, we need Breeder Reactors. For now, just think of “Breeder reactor” as a codeword for “Reactors that use fuel far more efficiently and produce much less waste”. I’ll give a more detailed explanation later in this post.

History teaches us that the big problem with breeder reactors is that their greater complexity makes them unaffordable. Remember, the primary goal I focus on is making nuclear energy cost less than fossil fuel energy, so that’s a big problem. Current LWR-based nuclear power costs more than fossil fuel energy, and the old-school style of breeder reactors would cost even more.

One of the biggest challenges is that the kind of breeder reactors that have been built before have required something known as a fast neutron spectrum design. I’ll spare you the technical details, and get to the bottom line: That makes them cost more. A lot more.

LWRs use a much simpler (and some would argue, safer) design approach called thermal spectrum. Simply put, “thermal spectrum” is just a fancy nuclear way of saying “the neutrons flying around inside the reactor are moving slower, with less energy, and are easier to manage”. The problem is, there’s no known way to make a uranium fueled breeder reactor work in thermal spectrum. Uranium-fueled breeder reactors only work in fast neutron spectrum, and that makes them too complex and expensive to deploy at scale economically. Achieving optimal efficiency in fast neutron spectrum is only possible in much larger reactors—typically 5 GWth or more. So fast breeder reactors, a term referring to breeder reactors that work with fast spectrum neutrons, inherently tend to be extremely big, extremely expensive reactors.

To achieve the goal of making nuclear energy cost less than fossil fuels, we need to mass-produce breeder reactors in factories on fully robotic assembly lines. How can you mass-produce gigantic 5 GWth nuclear reactors on an assembly line and make them more economic than fossil fuel energy? You can’t. And even if you could, they would be too big to move from the factory to the power plant after they were built. So you’d have to do at least some of the construction on-site, making them even more expensive.

So we need to somehow figure out how to make breeder reactors that work in thermal spectrum, and mass-produce that kind of breeder reactor to make them cost-competitive with fossil fuels.

Guess what? There’s only one known way to make a breeder reactor work in thermal spectrum: Switch from Uranium to Thorium as the primary fuel source. And in my opinion, the most optimal thermal spectrum breeder reactor design for making nuclear cost less than coal & gas is the Thermal Spectrum Molten Salt Breeder Reactor, or TS-MSBR for short.

China’s TMSR-LF1 was designed to be the first step toward commercializing the TS-MSBR. The TMSR-LF1 isn’t a full breeder reactor—that will come later. So technically, it’s just a “T-MSR”, for “Thorium Molten Salt Reactor”, without the “B” for Breeder. But there can be no doubt that China’s ambition is to develop a mass-production compatible thermal spectrum breeder reactor which is fueled by Thorium, a fuel source China has enough of under its own soil to power the entire planet for thousands of years. (United States, India, and Australia all have thousands of years’ worth of Thorium reserves as well).

And to be clear, I contend that whoever commercializes a breeder reactor that can be mass-produced at a cost that makes nuclear energy cheaper than coal & gas will achieve a degree of energy dominance that will change the course of world history. China is way out in the lead on that front, and I congratulate the Chinese for their leadership and success. But now it’s way past time for the West to catch up. If we don’t, China will eventually develop nuclear energy that’s cheaper than energy from coal & gas decades before the West does, and that will completely redefine the balance of geopolitical power in China’s favor. More on that in Part III.

Should we abandon LWRs?

Am I saying that LWRs are the wrong technology to “Triple Nuclear by 2050”, and that we need to switch to breeder reactors to achieve this goal? NO! Absolutely not. LWRs are exactly the right technology to Triple Nuclear by 2050, and I strongly advocate building more of them in pursuit of that exact goal. They’re the proven technology that works today and is supported by decades of operational experience. But LWRs simply cannot scale to the degree needed to replace fossil fuels. That would be impossible, and I’ll show you why in this post.

The problem is bigger than you might think

Here’s the rub: Tripling nuclear by 2050 (and that’s about as much as you could realistically build using LWR technology with a once-thru fuel cycle) barely makes a dent in the problem of replacing the energy we now derive from fossil fuels. To replace all the energy we get from fossil fuels would require 24x current nuclear capacity, not just 3x. And I contend that it’s simply impossible to build 24x current capacity using once-thru fuel cycle LWR technology. I’ll explain what I mean by “once thru fuel cycle” later in this post, but first, let’s look at some charts to drive home my point.

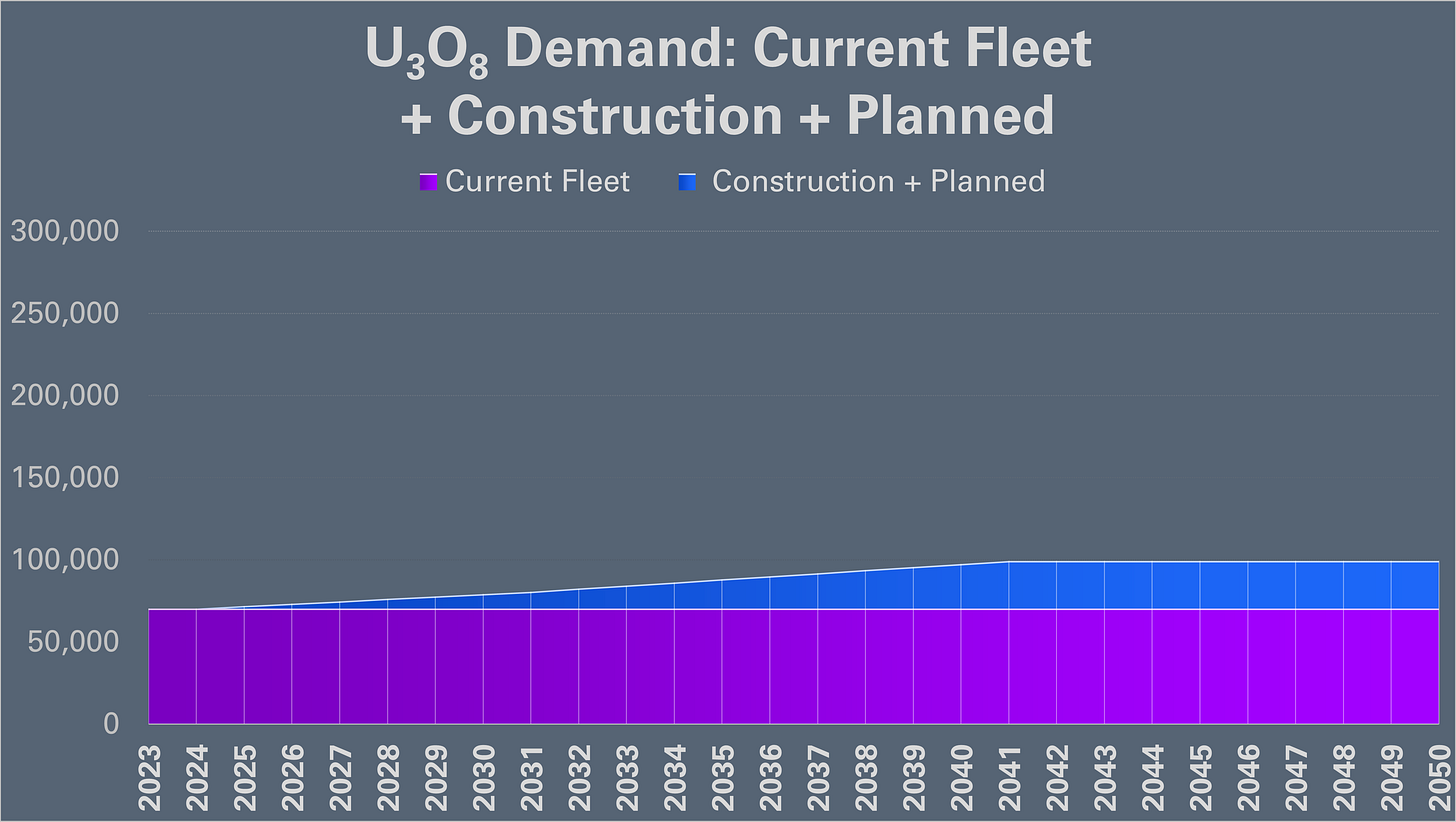

The current fleet of 411 reactors produces ~371 GW of electric generation capacity and consumes about 70,000 metric tons (mt) of natural uranium annually. Reactors planned or already under construction will raise that figure to 100,000mt of uranium demand by 2040:

U3O8 is the chemical formula for uranium oxide, the natural uranium we can mine out of the ground to make nuclear reactor fuel from.

Spent nuclear fuel “waste” isn’t nearly as problematic as the public has been led to believe by anti-nuclear activists, and calling it “waste” doesn’t even make sense. It’s actually valuable nuclear fuel that we should be recycling to power new advanced reactor designs, but that’s a topic for another article. We now have well over 250,000mt of spent nuclear fuel “waste” in dry cask storage at nuclear power stations all over the world:

If we stick with the same LWR reactor technology and continue to use the same once-thru fuel cycle (meaning we don’t recycle the waste as we should), then tripling nuclear will both triple uranium demand and triple the amount of spent nuclear fuel waste in storage:

Opinions vary among industry analysts as to whether it’s realistic to scale the uranium mining industry up to producing almost a quarter-million metric tons of uranium by 2050. It’s definitely ambitious, but it my opinion not impossible. However, it should be noted that uranium prices have to go much higher in order to incentivize building all the uranium mines that would be needed to triple nuclear by 2050 using LWRs and the current fuel cycle.

Tripling nuclear without reforming our “waste” management policies would also triple spent fuel waste in storage to about 750,000mt by 2050. The public fear about nuclear waste frankly isn’t rational and is not based on a clear understanding of the risks involved, but the fact remains people won’t stand for this. So at a minimum, if we’re going to triple nuclear by 2050 using LWR technology, we need to reform our policies and start reprocessing spent nuclear fuel.

Now let’s consider what it would take to fully replace all the energy we now derive from fossil fuels with LWR-based nuclear energy using the once-thru fuel cycle. Before we even get to the topics of uranium demand and waste generation, we can pretty much rule this option out because we could never afford to build that many conventional LWR-based nuclear power plants.

The nuclear power industry has a long history of underestimating what it will really cost to build a nuclear power station. I make a firm rule of ignoring reactor manufacturer’s “projections” and “estimates”. Instead I insist on basing my analysis on what real-world experience teaches us about how much it really costs to build nuclear power stations. The statistics are sobering, so put your seat belt on…

There are two recent project completions we can use as benchmarks to gauge the real-world cost of building nuclear power using LWR technology. The first is the Vogtle powerplant near Waynesboro, GA. The Vogtle #3 and #4 reactors are Westinghouse AP1000s that were just completed in the last couple of years, and are now fully operational. Building them literally bankrupt Westinghouse in 2018 after massive cost and schedule overruns plagued the project, which first broke ground on construction in 2013. The usual way to measure the CAPEX (capital expenditure, or cost of construction) for nuclear power is in $ per KW of electric power generation capacity. When the dust finally settled, Vogtle #3 and #4 cost just over $16,000 per KW! Compare that with about $1,000 per KW for an economically built gas-fired powerplant.

In fairness, critics of my analysis would correctly argue that Vogtle is a bad example because a whole bunch of things went wrong on that project, and it “should” be much better next time around. I definitely agree that it should cost less than that to build a LWR-based nuclear power station. But the fact remains that Vogtle was the first reactor completion in the United States in more than three full decades, and the bottom line is the bottom line: We’re just not as good as we used to be at building large bespoke public works projects on time and on budget.

If we can’t solve that problem, building enough AP1000s at Vogtle prices to fully replace all the energy we now derive from fossil fuels would cost $148 trillion dollars, or more than 20% more than the M2 money supply of the entire planet!

I’m sure we can do better, and that point is exemplified by the only other recent major reactor project completion: The Barakah power station in the United Arab Emirates. The UAE chose the South Korean APR-1400 reactor design, which is very similar in terms of technology to the AP1000. They built a 4-reactor power station for just over $4,000 per KWe, or about one quarter of what the Vogtle project cost. So it’s definitely possible to be much more efficient at building LWRs, and my hat is off to the Emiratis for doing a brilliant job with Barakah.

But even at Barakah prices, it would cost $51 trillion dollars, or just over half of the global M2 money supply to build enough LWRs to fully replace all the energy we get from fossil fuels. I contend that the TS-MSBR reactor design that China is currently in the lead on commercializing could eventually be mass-produced at scale for a cost under $1,000 per KWe, or about the same as the most economical gas-fired power plants. That would bring the CAPEX required to fully replace fossil fuels down to well under $10 trillion, or about twice what we’ve already spent on wind and solar energy, for the sake of capturing less than 5% of global primary energy demand.

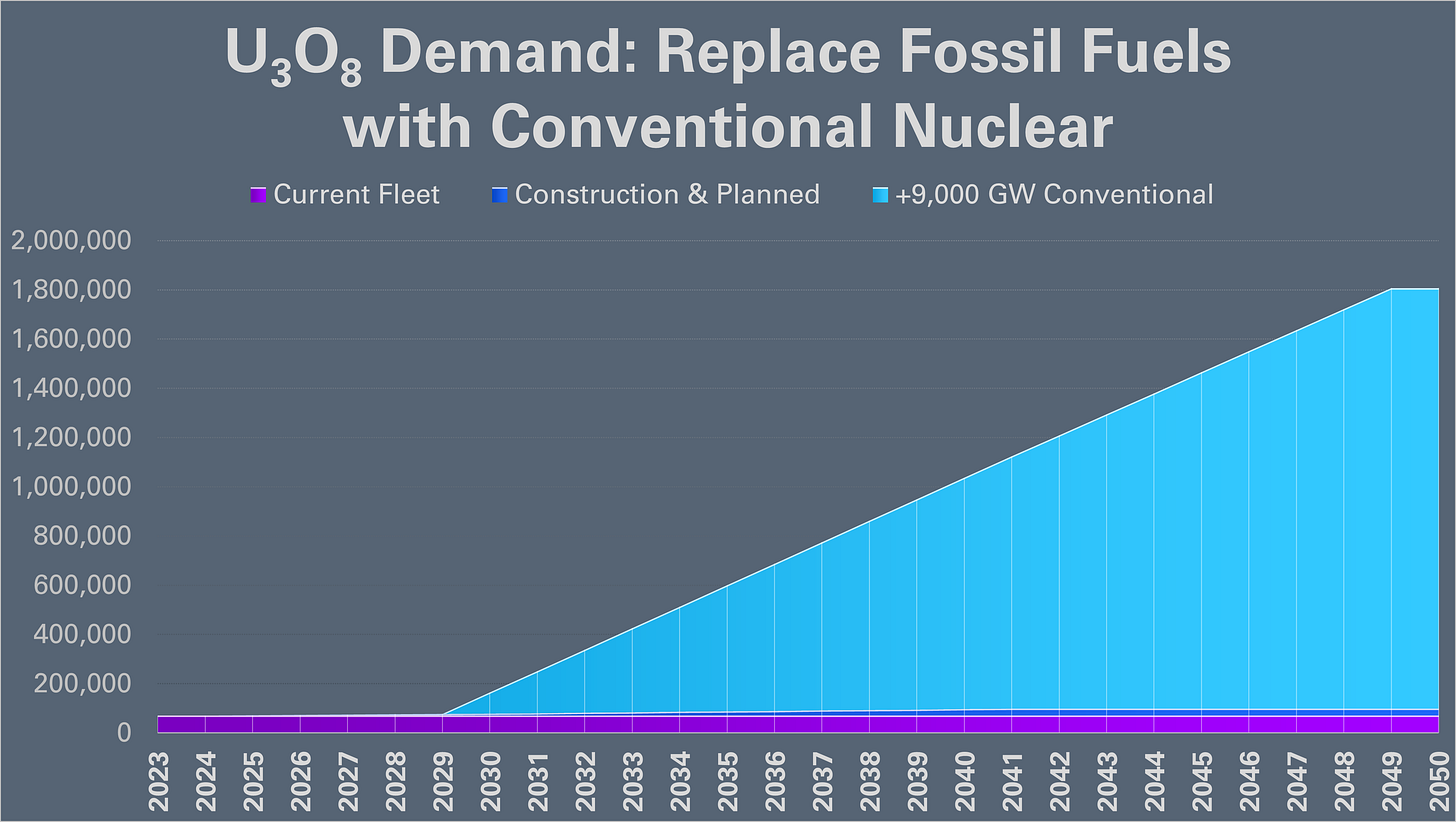

If the economic arguments weren’t enough to convince you, I’m confident that the uranium demand and waste statistics will. Here’s what Uranium demand would look like if we tried to replace all the energy we get from fossil fuels using LWRs on a once-thru uranium fuel cycle:

I don’t know of a single credible analyst who thinks it remotely possible to scale up uranium mining globally (at any price) to produce 1.8 million metric tons of uranium. So this scenario simply is not possible, period, end of story. Even if it were possible, look at what would happen to spent fuel waste if we don’t first reform our ways and start recycling our spent nuclear fuel:

Yes, that’s nearly three million metric tons of nuclear waste by 2050, and a very steep trajectory of further waste accumulation after that. Try selling that one to the Sierra Club’s next annual meeting!

Don’t worry, we can solve all these problems. But not with once-thru fuel cycles and LWR reactor technology. LWRs can get us to the “triple-nuclear” objectives, and we should definitely keep building these reactors based on proven technology. But in order to solve the much larger problem of fully replacing the energy we get from fossil fuels with nuclear energy, we simply can’t do that without adding breeder reactors to the calculus. And history teaches us that fast neutron spectrum breeder reactors tend to cost way too much to be economically viable for civilian nuclear power. The solution (according to me, anyway) is to mass-produce thermal spectrum breeder reactors fueled by Thorium, and I’m not the only person to think that. China “gets it”. In spades. And I contend that the TMSR-LF1 is just the first visible step in China’s journey toward commercializing and ultimately mass-producing the TS-MSBR.

Nuclear Fuels

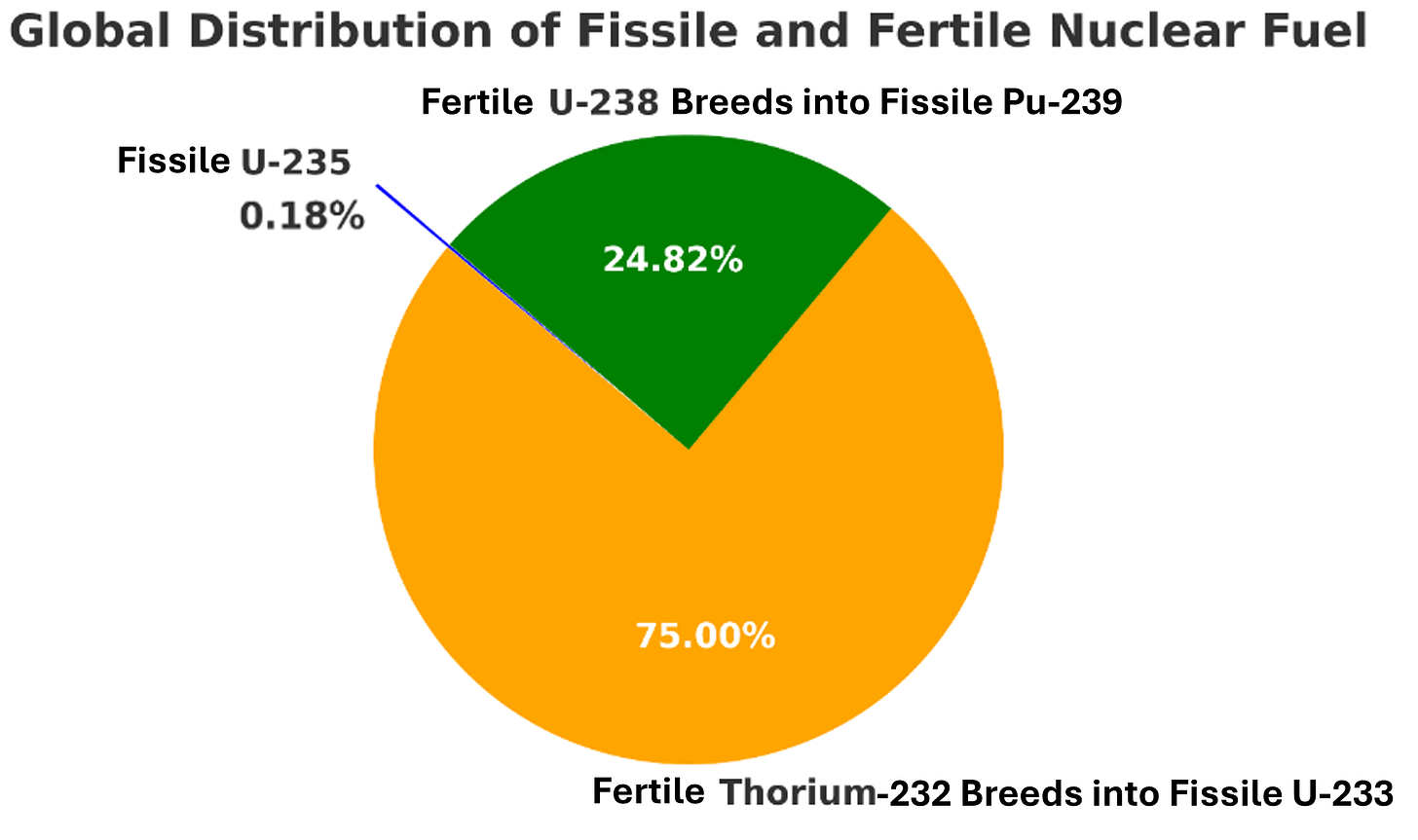

To sustain a nuclear fission chain reaction (i.e. to fuel a nuclear reactor), you need a fissile isotope. There are only three viable candidates and just one of them (Uranium-235) occurs in nature. Two others (Plutonium-239 and Uranium-233) can be manufactured through a process known as breeding. That’s it; there are only these three choices for nuclear fission reactor fuel, and no others.

The only fissile isotope that occurs in nature is Uranium-235, and it’s incredibly scarce. Only 0.7% of the uranium we can mine out of the ground is U-235; the rest is U-238. And that’s why uranium has to be enriched (at considerable expense) before it can be used to fuel a LWR. Here’s the breakdown of the nuclear fuel we have available to run Planet Earth for the entire duration of the Age of Nuclear, which I predict will last about 250 years:

That teensy-weensy little blue sliver in the upper left quadrant of the chart is Uranium-235. It represents less than 0.2% of all the fissile and fertile nuclear fuel we have available to run our planet for the next few hundred years (if you accept my premise that nuclear should be our primary fuel source by the end of this century). But virtually all of the current fleet of LWRs run almost exclusively on U-235.

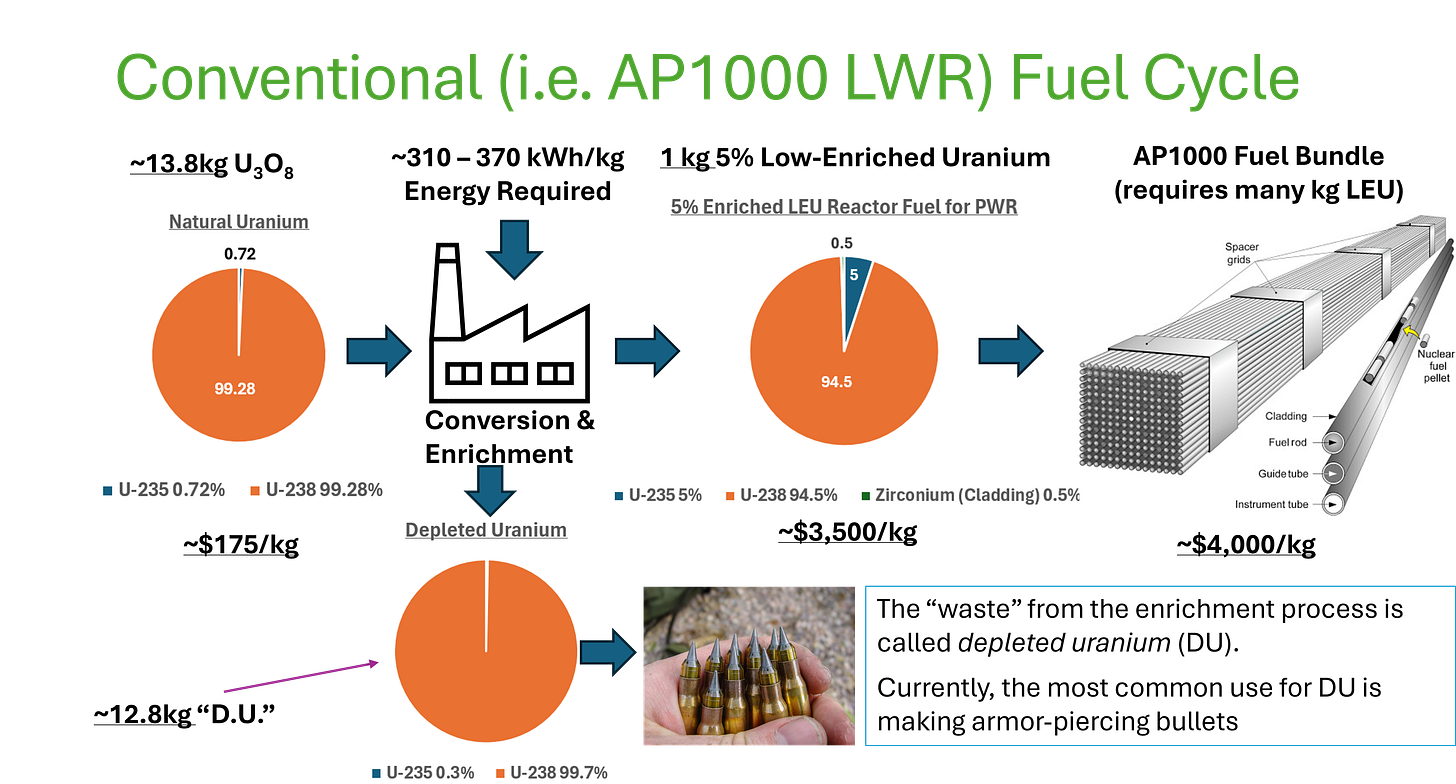

Today’s fleet of LWRs are fueled by Low-Enriched Uranium, or LEU for short. LEU is typically 3% to 5% U-235. The remaining 95% to 97% is U-238. Here’s how the fuel cycle for a LWR fueled by 5% LEU works:

A full load of fuel for an AP1000 is about 80,000 kg (i.e. 80mt), but to illustrate how the fuel cycle works, the graphic above just shows the process to make 1kg of that fuel. We would need to do this 80,000 times over to make a full load of fuel for an AP1000.

We start with about 13.8 times the amount of natural uranium as we need in enriched reactor fuel. So to make enough 5% LEU to fuel an AP1000, we’d need 13.8 x 80 mt = about 1,104 mt of natural uranium. The process of enriching those 1,104 metric tons of uranium will yield 80mt of 5% LEU reactor fuel, and about 1,024mt of leftover depleted uranium (DU), which goes completely to waste for the most part today. We use some of it to make armor-piercing bullets (because it’s even heavier than lead), but the rest goes to waste.

I can’t stress this point strongly enough: All that U-238 going to waste is perfectly good nuclear fuel we can and should use to fuel the global economy. The wasted U-238 in DU contains many times more energy than the amount the reactor actually consumes by burning the U-235. But to use that U-238 efficiently, you need fast-spectrum breeder reactors, and history has taught us that so far, at least, that kind of reactor is too expensive to build an economically viable civilian nuclear power plant with. More on that later—now let’s return to the AP1000’s fuel cycle.

We’ll assume the fuel for the AP1000 is 5% U-235, and 94.5% U-238. (Westinghouse actually recommends 4.5% to 4.8% LEU, but let’s stick with round numbers). The remaining 0.5% is the zirconium alloy tubing used as cladding to house the LEU fuel pellets, turning them into rods. LWRs are incredibly inefficient in how they consume uranium. All of the uranium fuel could and should be used to make energy. But only the U-235 is fissile and can directly sustain a nuclear fission chain reaction. It’s possible to breed the U-238 in the fuel into fissile Plutonium-239, which can then be consumed as fuel to help sustain the fission chain reaction, but today’s LWRs are not designed to do that.

Only about 1-2% of the U-238 will transmute into Pu-239 in an LWR. Of that 1-2%, about half will be burned to help make electricity, and the remainder winds up in the spent fuel “waste”. This transmutation of fertile U-238 into fissile Pu-239 happens almost by accident; although LWRs are not intentionally designed for breeding fertile isotopes like U-238 into fissile isotopes like Pu-239, there are enough neutrons flying around inside the reactor that some of them get absorbed by U-238 atoms, transmuting them into Pu-239. Breeder reactors (discussed later in this post) are specifically designed to transmute a much higher percentage of the fertile fuel into fissile fuel that can be burned to make energy.

The main point I want you to take to heart is that LWRs consume less than 5% of the energy contained in their LEU fuel to make electricity. The remaining 95%+ is still valuable nuclear fuel that we could and should consume in more efficient reactor designs, so the very idea that we call this stuff “waste” is crazy. The question we should be asking instead is, why are we wasting perfectly good nuclear fuel?

Using the fuel cycle discussed above and then just storing the resultant “nuclear waste” indefinitely is called a once-thru fuel cycle, or an open fuel cycle. You might hope that someday, someone will invent a way to stop wasting all that perfectly good fuel. You don’t have to wait—someday already happened. Way back in the late 1940s, when spent fuel reprocessing was first conceived. It took a few years to get the process working efficiently. By 1966 we’d opened the first nuclear fuel reprocessing facility in New York, but then President Jimmy Carter outlawed all reprocessing of spent nuclear fuel in the United states, and used a treaty mechanism known as Section 123 to effectively bully other nations not to reprocess their spent nuclear fuel either.

The tragedy of the once-through open fuel cycle is twofold: First, we’re wasting perfectly good nuclear fuel we should be using. But equally if not more importantly, we’re literally turning that perfectly good fuel into radioactive waste that has to be stored for thousands of years! Carter’s decision to outlaw reprocessing was absurdly misguided in my opinion, but that’s another topic for another post on another day.

The main point I want you to take away from this section is that today’s fleet of LWRs are only designed to use the 3% to 5% of the fuel that is U-235, the naturally occurring fissile isotope of Uranium. They only use at most 2% of the U-238 that makes up at least 95% of the fuel, and and that happens more by accident than by design. The rest of the fuel is completely wasted.

Breeder Reactors

The word breeding refers to transforming a fertile isotope (Uranium-238 or Thorium-232) into a fissile isotope that can sustain a nuclear fission chain reaction and be used as nuclear reactor fuel. But sadly, the terminology for reactors designed to transform one isotope into another gets pretty confusing. The nuclear industry could do better in standardizing this terminology.

Some people use the phrase breeder reactor broadly to mean any nuclear reactor that is designed to transmute fertile isotopes into fissile isotopes, then use those fissile isotopes as fuel to sustain the reactor’s fission chain reaction. Using that broad definition of “breeder reactor”, many of the new advanced reactors being introduced right now such as Terra Power’s Natrium reactor or Oklo’s Aurora reactor could be considered to be “breeders”. Those are both fast neutron spectrum reactor designs which aim to transmute a much higher percentage of the U-238 in the fuel into Plutonium-239, which is then consumed as fuel to operate the reactor for longer without refueling. In other words, they’re designed to use both the U-235 and the U-238 in the fuel they consume, and that makes them both much more fuel-efficient and able to produce much less waste.

That’s terrific progress, but I have some serious concerns about scalability of those designs because of the high-test HALEU fuel they require. HALEU is the same thing as LEU reactor fuel, but it’s enriched to more than 5% U-235. By definition, any fuel enriched between 5% and 20% U-235 is HALEU. But in practice, most of the advanced reactor designs being introduced now require 19.75% U-235 HALEU, just below the 20% legal limit which exists to thwart weapons proliferation.

Don’t get me wrong—I love these new reactors and I’m excited for Terra and Oklo. And I own some Oklo stock as well. I’d love to see them build a few hundred GW of new generation capacity with these fast spectrum reactors. But that just barely puts a dent in replacing all the energy we get from fossil fuels, and I just don’t think it’s realistic to come anywhere close to building all the energy we need with fast-spectrum HALEU-fueled reactors.

The good news is that at 19.75% U-235 and 80.25% U-238, there’s enough U-235 to both make lots more electricity and also to produce enough neutrons to transmute a much higher percentage of the U-238 into Pu-239 which also serves to fuel the fission chain reaction. So these reactors use a smaller amount of enriched fuel to make more electricity while producing much less waste. Win-Win! But here’s the rub: remember how it took 13 kg of U3O8 (natural uranium) just to make 1kg of 5% LEU? Well guess what? The ratio is more like 50:1 to make 19.75% HALEU! So while it’s true that the amount of 19.75% HALEU needed to make a certain amount of electricity is much lower than the amount of 5% LEU needed to make the same amount, the HALEU-fueled reactors actually demand more U3O8 in some cases than LEU-fueled LWRs. Recall this chart from earlier:

Since the HALEU-fueled fast spectrum reactors make much more electricity from a relatively light load of HALEU, it seems intuitively like they’d create less uranium demand than their LWR cousins, but in many cases they actually demand more. There just no way we could ramp up to supply that much U3O8 from conventional mines. There’s an experimental technology for extracting U3O8 from seawater, but it’s yet to be commercialized and proven to work. So repowering the global economy and replacing all the energy we get from fossil fuels with this kind of reactor just plain isn’t going to be possible due to insufficient uranium supply.

So let’s move on to the narrower (and technically correct) definition of the phrase breeder reactor. I sometimes use the phrase true breeder to make clear that I’m talking about this narrower definition. A true breeder reactor is one that produces more fissile isotopes than it consumes. That means it only needs a single initial fuel load containing a fissile isotope such as U-235. A true breeder reactor then transmutes fertile material (U-238 or Th-232) into fissile fuel that can sustain the chain reaction that powers the reactor indefinitely. The significance of this cannot be overstated! What it means is that once the reactor is up and running, the only fuel it ever needs for the rest of its life is more fertile material, which is cheap, abundant, and doesn’t require expensive enrichment!

Of the 411 reactors in commercial operation around the world today, only 2 of them are true breeder reactors. Both are in Russia. China and India are both working on their own true breeder reactor prototypes. The only possible way to make a true breeder reactor that breeds U-238 into Pu-239 is to design the reactor in fast neutron spectrum. The expense of such designs appears to be the reason that virtually all attempts to commercialize breeder reactor technology to date have failed.

The TS-MSBR: Breeding in The Slow Lane

You can’t build a true uranium breeder reactor in thermal spectrum (that’s the lower cost, simpler way to build a reactor using slow neutrons), but you can build a Thorium-fueled true breeder reactor in thermal spectrum. And there should be no doubt that the reason China is working so hard on their Thorium energy program is because they share my vision for repowering the entire planet, replacing fossil fuels with Thorium-fueled TS-MSBRs as the workhorse of energy transition. The TMSR-LF1 is just the first step along the journey to eventually mass-producing TS-MSBR on gigafactory assembly lines.

To put this in perspective, consider what it costs to run planet Earth today in terms of energy cost. The fuel bill to run the entire planet is six and a quarter trillion dollars per year. If we could somehow find all the uranium needed to run the whole planet on LWRs with a once-thru fuel cycle, and if we could somehow come up with the $51 trillion (at Barakah prices) it would cost to build all those LWRs, we could reduce the fuel cost by more than 60% to just $2.3 trillion. But if we were running on TS-MSBRs, the total fuel cost for all the Thorium we’d need to run the entire planet would be just $312 million. That’s a 99.996% reduction in cost from the $6.25 trillion it costs us to run on fossil fuels!

When I showed this chart to whatisnuclear.com founder Nick Touran, he immediately “called bullshit”, making the point that I was presenting the chart as if Thorium is the magic bullet here, when in reality the profound cost savings are a result of using true breeder reactors, not which fertile material they’re fueled with. Nick’s critique was that to tell this story honestly, I should add a column to show the cost of the depleted uranium needed to fuel a Uranium-to-Plutonium breeder such as Terra Power’s yet-to-be-built Traveling Wave Reactor, which uses depleted uranium as fuel much in the same way that the TS-MSBR uses Thorium as its primary fuel. Both designs only require one inital load of fissile fuel, then they can make energy forever on cheap, abundant fertile fuel alone.

But to do that with depleted uranium requires the complexity and expense of a fast neutron spectrum design. And to get the optimal neutronics for making the reactor work efficiently, a depleted uranium breeder would have to be a very large reactor—probably 5GWth. I can’t imagine how we could ever mass-produce those economically enough to base a global energy transition on them.

Nick was definitely right to call me out on not mentioning the option of depleted uranium as a fuel source for a uranium-to-plutonium breeder reactor, but the fact remains that doing that requires a much more complex fast neutron spectrum design. I’m still sold on the TS-MSBR as the best choice for mass-production, but I have a feeling Nick would disagree. Hopefully he’ll share his views in the comments below this post.

Repowering the Planet with TS-MSBRs

I’m convinced that the key to this is what I’ve called the Nuclear Henry Ford Moment. By that I mean seizing the economies of scale inherent to assembly line mass production to make nuclear energy cost less than fossil fuel energy. One company doing pioneering work on this front is Copenhagen Atomics. (Full disclaimer: I’m an angel investor in Copenhagen Atomics).

The Copenhagen Atomics WasteBurner is a 100 MWth reactor packaged in the form factor of a standard 40’ shipping container. The company’s goal is to make true TS-MSBRs in this form factor eventually, but the initial product will likely be a high burnup ratio T-MSR. In other words, it will get most of its energy from Thorium, but will still require “top ups” with a small amount of fissile material until they achieve true breeder capability in the mid 2030s.

Copenhagen has yet to prove that they can actually pack 100 MWth into a shipping container, and plenty of people (including whatisnuclear.com’s Nick Touran) have expressed skepticism. As the graphic shows, it takes about $20 million worth of coal to make that much energy for a full year, and Copenhagen proposes to make the same amount of energy from $1,800 worth of Thorium. That’s incredibly ambitious and has yet to be proven, but I’m waiting with baited breath for their first criticality experiments scheduled in early 2027.

If Copenhagen Atomics can eventually deliver on their vision of a 100 MWth reactor in a shipping container, I contend this reactor could change the world. The company believes it can mass-produce these reactors at a unit cost below $10mm. That implies that the reactor modules (which don’t include the steam turbines needed to produce electricity) would only cost about $250 per KWe. Yes, it will take more than just the reactor modules to build gigawatt-scale power plants, but all said and done my hope is that we’ll be able to build full-scale nuclear power stations from these container-sized modules in less than a year for less than $1,000 per KWe. Admittedly, that’s an awfully ambitious goal. But if we can pull it off, we’ll change the course of human history to a greater degree than the Industrial Revolution.

Conclusions

The main point here is that the way we can transform the global economy out of the 165-year Age of Oil and really turbocharge the nascent Age of Nuclear which I expect to last at least 200 years is to figure out how to deploy true breeder reactors at scale economically. Figure that out, and you can solve Energy Transition and Climate Change before breakfast, and usher in a new era of human prosperity on par with the Industrial Revolution by dinner time! Ok, ok, that’s a metaphor and it would really take at least a couple of decades to roll out, but you get the idea.

Tying this back to China’s TMSR-LF1, only one liquid-fueled molten salt reactor had ever been built before: The MSRE reactor at ORNL. Alvin Weinberg, the inventor of the Pressurized Water Reactor (the most popular style of LWR) was emphatic in his autobiography, saying that he believed molten salt reactors and Thorium as a fuel source being abandoned in the early 1970s was the greatest tragedy of the First Nuclear Era, and that he hoped they would be resurrected in the Second Nuclear Era, which I contend has already begun.

All signs are that China’s TMSR-LF1 is the first step in China taking this bull by the horns and beginning the path toward mass-production of TS-MSBRs fueled by Thorium, a fuel that China has enough of under its own soil to power the entire planet for millennia. I’ll have more to say about the macroeconomic and geopolitical importance of China being the leader on this charge in Part III.

I broadly agree with the need to have breeder reactors (eventually), but they are also not a panacea.

-Even if the core can be factory built, there will still need to be a seismically rated containment structure for them. If anything, it will need to be more robust to external events, as low pressure nuclear does not (typically) have ceramic fuels and fuel sheaths (the first two layers of protection from large scale releases for water cooled reactors)

-Economies of scale are also real, and large numbers of parallel units are not used in the chemical industry (the closest analog for low pressure nuclear) for the same reasons. The large number of units adds a lot of costs for instrumentation and control, and the multiplexing of flows adds many potential leak points and much higher O&M costs.

-Most of the cost of traditional nuclear equipment is for AQ/QC, not the actual materials or direct fabrication. This will apply just as much to low pressure nuclear as water cooled. Fix it for one, and we fix it for the other as well. There is a better balance here, but it is not trivial requirements still.

-Fuel costs are a small fraction of the overall costs of nuclear now (that could change for a HALEU/TRISO design though). While breeding cycles nearly eliminate the raw material input costs, the chemical processing of hot materials is also expensive. Don't expect to save much if any over say a CANDU natural uranium fuel cycle cost. Note that a Pa extraction step in a Th cycle has huge proliferation concerns, which adds costs.

I applaud anybody pushing for legitimate solutions for us to avoid/lessen the climate collapse which is under way already. Recent climate research paints a dire picture, and solar and wind are resource intensive products that require fossil fuels to make and have limited lifetimes to boot.

Smart folks like Arthur Berman largely dismiss wind and solar, and essentially say that it's naive to believe that technology will bail us out of the crisis we've created (e.g. there is no way for us to scale carbon sequestration to the extent needed).

Degrowth seems to be the only realistic way to stop the bleeding, but I understand that capitalism and the belief that we can have infinite growth in a finite world, is the religion of the Western world. Pushing to colonize Mars is more politically feasible than degrowth.

All that aside, I believe electricity only accounts for ~20% of energy usage, while the rest is for shipping, fertilizer, and various other production processes. You mentioned using nuclear to power freighters in the last article, but I've read that the density of fossil fuels is what allows for these commercial uses and differentiates them from sources like nuclear. I am sincerely curious... could the technology you propose be viable to power industries like steel and shipping?

A lot of folks would tell me that we're already cooked, while many more deny climate change and say drill baby drill, putting their foot on the gas while we drive off the cliff. One thing we know for sure, is that we're definitely cooked if we just give up and stop searching for solutions. Thanks for pushing for solutions.